Bonding of windings by JOULE effect, in direct current. The following are set: wire diameter, ohmic resistance of the winding, temperature to be reached, current density and the machine automatically calculates the voltage to be applied and the related time required. The process stops upon reaching the temperature (± 2° C), calculating the increase in temperature moment by moment and measuring the ohmic resistance variations. Possible viewing of the heating curve.

Work cycle: complete testing of the stator (see H5/NCP); if it is positive, bonding is possible, therefore the dielectric strength and SURGE are tested again to check whether any problems have arisen.

Stopping of the bonding operation in the event of abnormal heating curves due to the effect of any breaks in the wire or short circuits between coils.

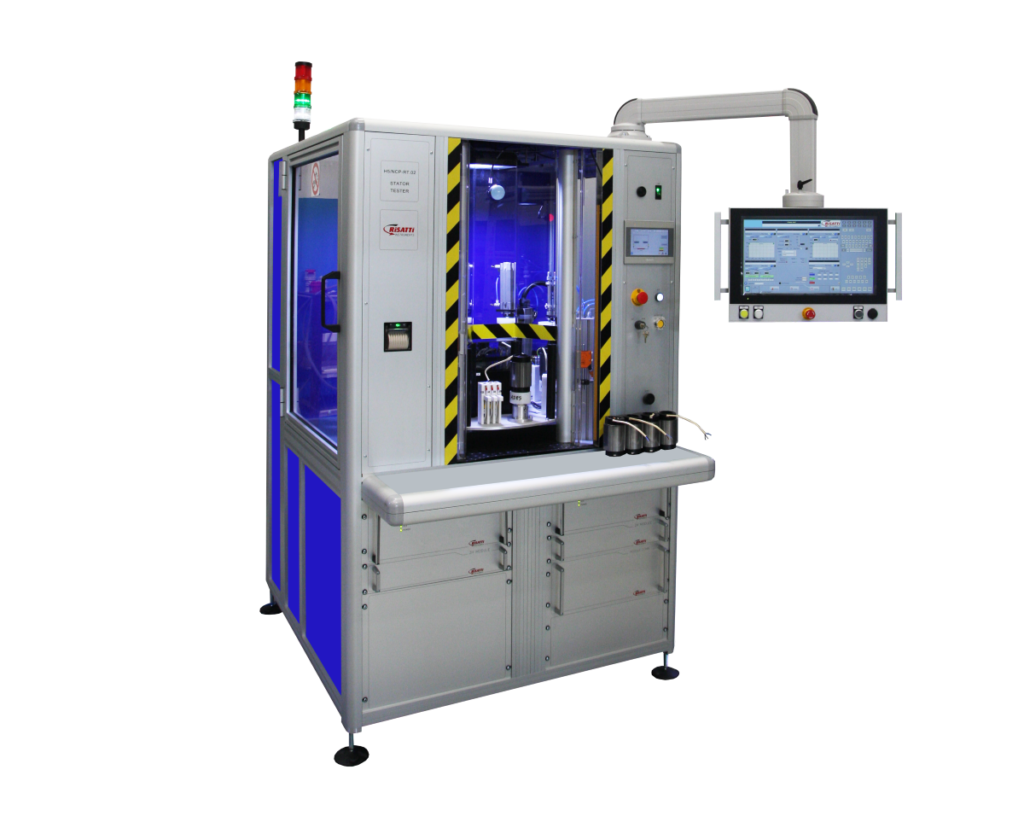

TESTING:

- OHMIC RESISTANCE

- DIELECTRIC STRENGTH

- SURGE

- ROTATION TEST

- BONDING

OPTIONS:

- Automatic systems (also robotic) for loading and unloading the pieces

- Laser marking for the good pieces also possible

- Possibility of automatic connection of the conductors (where provided) with color recognition, using a robot.